With the development from the numerical management technologies, there’s rapid advancement in the business of mechanical processing and flexibility at the production methods. The modern computer integrated manufacturing processes effectively create complicated geometries with high efficiency and at a lower price for low volume manufacturing companies instead of the traditional manufacturing procedure. Nowadays, today’s integrated manufacturing processes like CNC that entails using a computer for jobs such as drilling, and cutting techniques function as a favorable solution for both production and prototyping of automotive components worldwide.

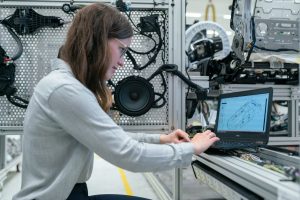

CNC Machine

The design and production of the mechanical components in contemporary CNCs are highly automatic. The pieces’ measurements are defined by employing some CAD applications that are later converted to manufacturing directives utilizing CAM (Computer Aided Manufacturing) software. The directives’ conversion into specific commands like G and M-codes is vital for the particular machine to generate the component. Modern CNC machines now being used are employing 5-axis machining.

The design and production of the mechanical components in contemporary CNCs are highly automatic. The pieces’ measurements are defined by employing some CAD applications that are later converted to manufacturing directives utilizing CAM (Computer Aided Manufacturing) software. The directives’ conversion into specific commands like G and M-codes is vital for the particular machine to generate the component. Modern CNC machines now being used are employing 5-axis machining.

The 5-axis machining empowers the functioning instrument to maneuver along five unique axes simultaneously, allowing machining of complex parts with total efficiency and precision. The precision CNC machines with AI support may also be employed to style programmed components with a feedback mechanism, aiding in the automobiles to self-drive. By way of instance, using a precision CNC system, a program was made to shut off a car mechanically if it’s left for a while with no human attempt from the code created by AI.

CNC Automotive

Every aspect of the manufacturing technique necessitates high performance. Thus, many machining methods are being utilized by automotive firms for the creation of unique parts like body sheets, windscreens, door panels and various external and internal elements. Automotive companies are participating in the CNC machines to get quicker production of exact and extremely efficient pieces. Using the CNC machine within the business of automotive is known as a CNC automotive. Several critical parts of the car can be made by utilizing the method of CNC automotive.

Every aspect of the manufacturing technique necessitates high performance. Thus, many machining methods are being utilized by automotive firms for the creation of unique parts like body sheets, windscreens, door panels and various external and internal elements. Automotive companies are participating in the CNC machines to get quicker production of exact and extremely efficient pieces. Using the CNC machine within the business of automotive is known as a CNC automotive. Several critical parts of the car can be made by utilizing the method of CNC automotive.

A motor’s cylinder is among these, where a sizable block of aluminum could be changed to an engine block or an engine cylinder at which the piston travels up and down in high speed and temperatures. Likewise, CNC automotive may be accustomed to the automobile’s exterior and interior lighting utilizing a substance such as oil glass or PMMA (Polymethylmethacrylate). Other elements like exhaust components, suspension components, carburetor housings, etc. could be fabricated using CNC automotive procedure since the whole process is relatively quickly producing authentic pieces. CAD enables quick adjustment of part’s layout; consequently, this manufacturing technology is beneficial in customizing the automobile and their parts.